Clients often ask how much freight fits on a full truckload. The answer isn’t exactly simple. It depends both on weight and volume. Here’s a simple chart to help you plan your full truckloads.

Clients often ask how much freight fits on a full truckload. The answer isn’t exactly simple. It depends both on weight and volume. Here’s a simple chart to help you plan your full truckloads.

With heat season just over a month away (many people start heating freight the first week of November), many transportation managers are wondering how they can avoid a shortage of heated trucks this winter. Especially, since freight capacity is already tight. Here are seven tips that will help you out this winter manager your heated freight capacity.

Many shipments are loaded with 90% of the freight being freeze tolerant and only 10% of the shipment requiring freeze protection or temperature control. Not only does this cost the shipper a premium but it uses up heated capacity where none is needed. Often by splitting the shipment into two, the cost of the increased LTL will be offset by reduction in the heated premium. This is easy to implement and your front-line shippers should be made aware of this option.

If you’re struggling to find heated trucks for a short run of less than a day, you may consider shipping without heat. While there is a slight risk involved in this practise, generally, liquids that are in motion will not freeze. Just like a river. Plus, the liquids will have some residual heat from the time of loading. For short runs, as long as you can work with your carrier not to leave the freight on the truck over night, you’ll probably be OK to ship without heat. Use your judgement here; extremely freeze sensitive material would not be worth the risk!

Blanket wraps are a great way to increase heated capacity. The idea is to wrap the liquid drums or totes in an insulated blanket. The residual heat in the product slowly dissipates over time. However, with proper calculations you can often ship freeze sensitive product over a few days without issue. The blanket manufacturers should be able to help you with grade, timing and temperature rules of thumb. The only downside to this method is you’ll have to ship the blankets back, so include that in your cost benefit analysis. Plus, there is some risk involved here. You should do your calculations carefully and include temperature probes and/or monitoring in your shipment.

In transportation, the term “heated” could mean a diesel powered portable heater in the back of a dry van, or it could mean putting the freight on a temperature controlled reefer unit. This may seem trivial, but when capacity is tight, you should consider what you actually need. If your product has a freeze temperature at zero or below, and the weather is not in a deep freeze of say -20C, then you should be OK with “heated”. That will open up your capacity to a much wider range of carriers with portable heating units. However, if you state “must maintain between 5-10C, then you are limiting yourself to a temperature controlled reefer unit. This will limit your options, if you don’t actually need that specification.

If you happen to have the opportunity to ship between A and B (or very close points) let’s say the points are Chicago and Toronto, and you have heated freight from Chicago and non-heated from Toronto, then you can work with your carrier to send out a heated unit and work out a deal to buy the backhaul in advance. Your carriers will love this, it makes their life easier and you just made your life easier by covering that heated shipment.

Book early when you can. Carriers have to plan their truck dispatch constantly. Much of the time based on unknowns. If you can provide your carriers with as much information as possible by booking early, they can often plan to have the right equipment where you need it.

XTL has made a significant investment in temperature controlled trailers over the last few years, including specially designed TEMPSOLUTION trailers that precisely monitor and maintain temperatures for very sensitive goods like pharmaceuticals, chemicals and food grade additives. If you’re worried about heated capacity this winter, now’s the time to contact XTL for a review of your needs.

On-time deliveries are a key performance metric for your supply chain and transportation providers. However, it can be really confusing to measure and manage. Here are some key things you should understand before defining an on-time metric.

The first thing you have to know about “on-time” is there really is no such thing. “On-time” is more of a concept than a reality. This may shock you, but here are some examples that make “on-time” difficult to measure.

I could go on, but if you’ve spent any time in the transportation industry you could probably list 100 different scenarios that you would consider late, or not late, etc. The crux of the problem is your trying to put a static measure on something that’s fluid. Pick up and delivery times change constantly because of all kinds of factors. Trying to pin down on-time/not-on-time is an oversimplification of a bigger problem.

First, you have to recognize the bigger picture. There are numerous parties involved and numerous causes for scheduling changes. The key to managing this picture is deciding on what to measure. One of the best ways is to just measure the all reasons for re-scheduling an order.

For example:

If you did a fishbone diagram or a pareto chart, it would help you in finding as many reasons as possible.

The second step is to gather all the reasons and sort them by responsible party. For example, you could put them into categories like: Shipper, carrier, consignee, Other. Weather and random customs inspections would be an “other” category for example.

Now that you have some order to classifying reschedules you can start measuring the reasons for re-schedules and the ultimate goal is to reduce the total number of reschedules.

Now that you have a clear picture of what’s going on in your supply chain, you can have really productive discussions and problem solving sessions with you vendors, carriers and customers. Less rescheduling normally means things go smoother all around, and when things go smoother, costs are reduced and customers are happier.

XTL’s staff are logistics experts. If you’re trying to reduce costs or improve service in your supply chain, contact XTL today for a free discussion with one of our logistics experts.

Transportation security is a big issue in the supply chain, not only to keep insurance cost low, but to prevent stolen merchandise from ending up in the black market. Here are 7 easy tips to improve your transportation security.

This seems obvious, but it’s surprising how many companies will ship with a new and unknown carrier to save $100 on a shipment worth thousands of dollars. Not that there is anything wrong with small 1-2 truck carriers, but they just don’t have the systems in place for things like: hiring policies, satellite tracking and check ins, etc. Check out your carriers, get references and make sure they have been in business for a long period of time with a good safety record.

If you’re shipping LTL, use good quality stretch wrap and add a couple of extra layers. Wrap it tight. This simple measure can help reduce a missing box, or a box getting broken into. At least if it happens, you have strong evidence for a claim!

While this is not fool-proof, it is a deterrent. If a thief has a choice of two trailers, one with a pin lock and one without, guess which one he’s going to choose. A good quality pin lock and a system to ensure they are used goes a long way in securing dropped trailers.

Most theft occurs when trailers are dropped and left un-attended. Try to avoid this situation as much as possible. If you have to drop, make sure it’s in a secured yard that has a guard. Otherwise, it’s just an invitation for a thief.

It’s amazing how many shippers don’t implement this. They load thousands of dollars worth of freight on a truck because a driver shows up and says, “I’m here for the load to Canada”. He get’s loaded and he’s gone. It’s a surprise later when the actual booked carrier shows up later for the shipment. Make sure you ID your carrier either by the name on the truck and match it to the one booked, or get the driver’s ID and make sure he works for the company booked with.

Carriers that are part of the FAST or C-TPAT programs have already been verified by government bodies for their compliance to various security standards. Simply choosing one will increase the level of security of your shipments.

A wire seal isn’t going to stop anyone looking to steal a shipment, but it does discourage tampering and a few missing boxes type of theft. At least if theft happens, you’ll have evidence it happened during transport and increase your chances of a successful claim.

XTL is both a FAST and C-TPAT carrier. We take load security very seriously. If your concerned about the security of your shipments, give us a call to discuss how we can help you.

This is probably one of the biggest issues that causes strife between carriers and distribution departments more than any other. This article explores options and consequences of different shipping/receiving department scheduling philosophies. At the heart of this issue is that carriers get paid by the mile, so they don’t want to wait to get loaded/unloaded, and shipping departments get paid by the hour, so they don’t want to be standing around waiting for trucks to arrive, or add extra labour to accommodate the small periods of “busy” times during the day when trucks show up.

Depending on who you ask, some people love this method of scheduling trucks for pickup and delivery and others hate it. This practise tends to favor the shipper and receiver at expense of the trucker. Usually, it means that the shipping/receiving department has limited resources and has the trucks wait in queue until they are able to be served. Sounds fair right? If you get there first you get unloaded first. However, truckers get paid by the mile and not by the hour. Having to wait 2-3 hours to get unloaded is unreasonable for the carrier.

This system is not without benefit for carriers some of the time though. If a carrier can show up “anytime on Tuesday” for delivery, they get flexibility in when they have to be there and it really helps them when unforeseen delays occur like weather and traffic.

Best of both worlds? A FCFS system with enough internal resources at the shipper/receiver to handle the busiest times. However, now this becomes expensive for the shipper, they’ll have labour sitting around 90% waiting to serve the 10% of the time when it’s busy.

Some people love appointment scheduling, others hate it. Similar to FCFS, it has both benefits and drawbacks. Appointment scheduling is great for carriers when they arrive on time and get in and out fast. It’s also great for shippers/receivers because they can plan the load on the department in advance and arrange for the appropriate amount of labour. This sounds like it’s efficient for everyone! It can be! However, when uncertainty creeps in, it causes problems for this system. If a carrier gets stuck in traffic, has a breakdown or gets delayed at a prior, all which is in a day’s work for a carrier, then the system breaks down. If Carrier A shows up for his 10am appointment at 10:30 due to getting stuck in traffic, there is no one to unload him because the labour is already committed to serving the 10:30 appointment who is there on time. This is fair right? Make him wait till 4pm when all the other deliveries are unloaded. Not really. It shouldn’t be a punishment to deliver at your facility! Strict adherence to a scheduling system causes a lot of bad feelings with carriers who do their best to get your freight delivered. On the other hand, always accommodating late appointments will earn you the reputation as “the last delivery”. You’ll forever be accommodating late deliveries.

There really isn’t a “perfect” solution to this problem. Each shipping/receiving policy has cost consequences for both the shipper and the carrier. Any cost absorbed by the carrier, will eventually find its way back to the shipper in the form of rates increases. So the optimal solution has to be a cooperative one. One which balances the needs and resources of the carrier with the needs and resources of the shipper.

XTL Transport has been helping customers with logistics problems for close to 30 years. If you’re looking for ways to reduce cost, improve service, or just reduce headaches, then XTL has solutions for you. Please contact us for a free consultation.

If you’re having difficulty getting shipments moved in the capacity crunch of 2014 then this article is for you. Trucking has been booming for the past few quarters. Record amounts of shipments are ready to move and carriers didn’t add capacity over the last few years because of the slow economy. Compounding this issue is the supply of truck drivers entering the market is just not enough to keep up with demand. All these factors have lead to a very tight market for trucks.

A carrier’s day is very complex. It requires coordination of people, materials and equipment across huge geography. To add to this, much of what they plan is unpredictable like the weather, traffic conditions, and border wait times. If you have flexible pick up times this really makes your location attractive to carriers. If they know they have a large pick-up/delivery window then it’s so much easier for their people do deal with the unforeseen and still be able to pick up and deliver. Consider more flexible pick up times in shipping/receiving department to attract more carriers to your lanes.

There’s a lot of equipment sitting idle on the weekends waiting for pick-ups or deliveries that can only be done on Monday. If you offer weekend deliveries, this may be attractive to carriers during the capacity crunch because it frees up equipment and eases the load on Monday deliveries. If you accommodate weekend pick-ups, a carrier who would otherwise have to layover a driver until Monday would be happy to pick up your shipment.

Truck drivers get paid by the mile, not by the hour. Nothing aggravates a driver more than having to wait for long periods of time to get freight loaded, wait for paperwork, Certificates of Analysis, customs documentation or anything else preventing them from driving. If your facility has a good reputation for getting drivers in and out fast, you’ll have carriers lined up for your business.

This is another way to offer carriers not only a fast turnaround but a commitment of future freight. To set up a drop trailer has a small investment to spot the trailer, but offers the carrier quick turn-around. The trailer can be loaded in advance and the carrier just has to drop the empty and hook up the full. Fast and easy! Plus, the carrier knows they’ll get repeat business because their trailer is there. This is a great way to make things easier for everyone and get a capacity commitment from your carriers.

Carriers have a very difficult business to run just like you do. Their business runs on information for the most part. They have a huge task of coordination to undertake every day. If your freight is tendered at 34,000 lbs, it should be 34,000 lbs when the carrier gets there, not 36,000 lbs. Being fair, open and honest about your freight and the requirements helps the carriers plan better. If you have a reputation for being fair and authentic, then carriers will be glad to do business with you.

An extension of being fair and authentic is to clearly outline requirements for the carrier. If you’ve committed to pay in 30 days, pay in 30 days. If you’ve promised a 1 hour load time, load in 1 hour. If you’re clear and consistent without any surprises, you’ll have a good reputation with the carriers and they’ll choose your freight over someone else’s that may come with “problems”.

Many shipping departments close at 5 pm. This leaves the carrier rushing to get there during rush hour traffic and if he’s a few minutes late, he misses the load and has to layover. This is a big deal for carriers. If you have the ability to load until 9pm or midnight even, offer this to the carriers. Many will jump at the chance for a late pick up because it saves them the layover and avoids rush hour traffic.

Make your driver waiting area comfortable and treat the drivers with respect. Offer them washroom facilities and maybe a free coffee. This goes a long way with the drivers. You’ll get a good reputation of a great place to pick up and deliver. Carriers will want to do business with you and drivers will want the loads.

Make sure you’re offering competitive rates. In the tight market of 2014, rates you paid during the recession are just not realistic. Make sure you’re paying with the market and you’ll be more likely to get your shipments moving.

It can be expensive, but sometimes if you have no other option, splitting a Truckload shipment into two LTL shipments can open up new opportunities to get your freight moving.

XTL has solutions for both truckload shipments and LTL shipments through XTL Logistics. We can help you find capacity and get your shipments moving. Contact us.

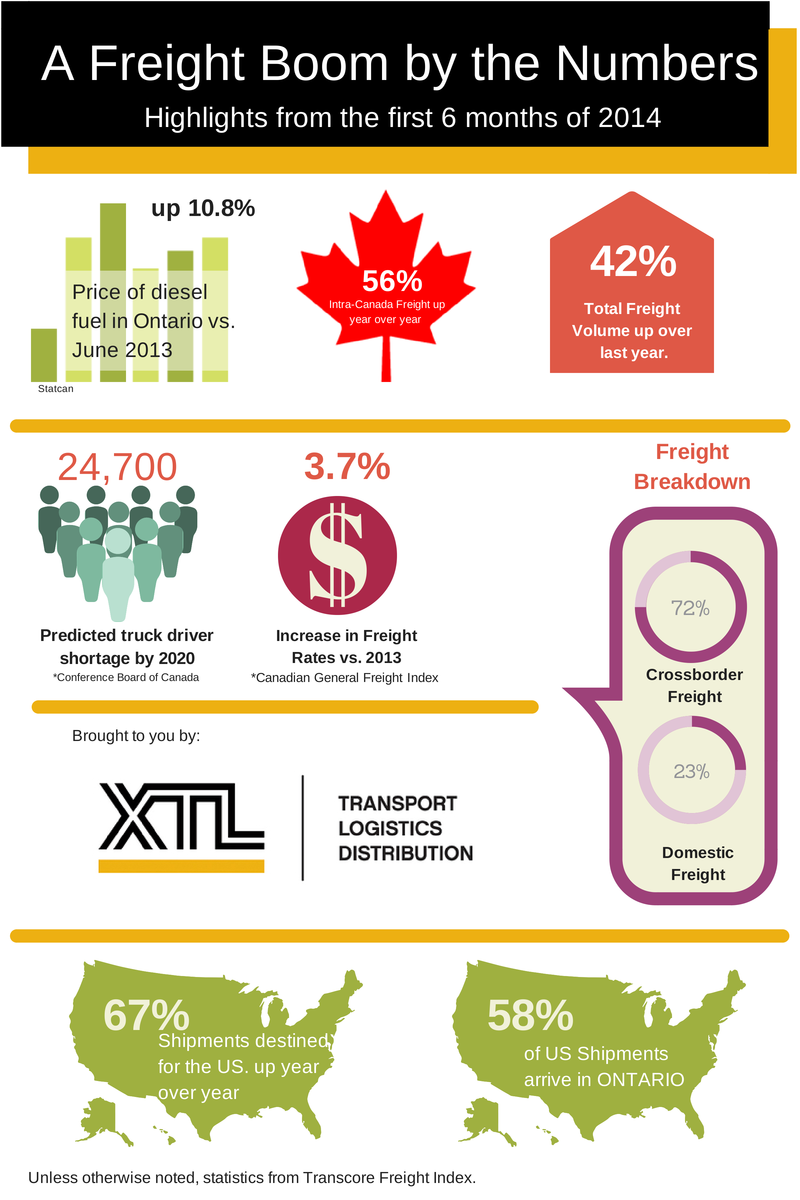

The Ontario Trucking Association is reporting what looks to be the start of a banner year in the trucking industry. With 42% of carriers reporting improved volumes this quarter within Ontario and almost half of carriers reported (48%) that volumes to/from the US increased.

At the same time, TransCore Link Logistics, a leading provider of freight matching services reported opening the year with never before seen highs in load volumes posted on their network. January was reported to be 47% up year over year. Link also reported that transborder postings were up 65% year over year for shipments originating in Canada and up 42% for shipments originating in the US.

It doesn’t appear pricing has taken on a dramatic upswing despite the growing freight volumes. However, signs of rising prices are evident with the OTA reporting that 23% of carriers were reporting higher rates in Q1 2014. This is surprising given that the industry has been in a capacity crunch for years. One would expect this number to be much higher. As the market tightens and capacity is further squeezed, it’s likely there will be more upward pressure on pricing in the months to come.

Diesel fuel costs are back on the rise. After a year of declining prices, the on-highway price of diesel fuel has risen back over $4.00/US per gallon. If rising freight volumes are the sign of a strong economy, the demand for diesel usually goes up and results in higher fuel prices.

Based on the economy regaining strength, and excessively positive signs from the trucking industry in Q1 2014, it looks like the industry is in for a busy and profitable year. High freight volumes will inevitably translate into a capacity crunch, allowing carriers a choice of better paying freight, resulting in on average higher rates and better margins for carriers.

Here at XTL Transport we’re excited about 2014 and have just been listed in Today’s Trucking as #20 on their Top 100 List of the Largest Carriers in Canada. We’re bullish about the future and are standing by to help our customers get their goods delivered safely, on-time and in an economical matter. If you’re experiencing the capacity crunch this year and haven’t tried XTL in the past. We’re here to help you.

Over many years in the transportation industry I’ve come to recognize that the biggest issue to impact service in terms of cost and/or on-time pickup and delivery is miscommunication between the carrier and the shipper. Here’s my top 10 list of common miscommunications that impact service.

Accurate freight weight and size is critical for both Truckload and LTL carriers to make sure that the freight both fits on the truck and doesn’t put the trailer over weight, or out of balance. Planning a load, particularly for LTL is an arduous task. Inaccuracies in the weight can make an entire shipment plan no longer work. One miscommunication about freight weight/size could potentially impact several customers.

Either the wrong address or a change of address can adversely affect a shipment. Sometimes the mailing address of shipping point is communicated to the carrier when the warehouse could be located blocks away. The second type of wrong address miscommunication is where a regular shipper moves and neglects to tell the carrier or their suppliers. Sending the carrier to an old address not only results in extra charges for all involved, but may impact the delivery if the driver runs out of hours driving to the new address.

The miscommunications that can happen with a HAZMAT shipment could almost be their own top 10 list! It’s critical to get the right HAZMAT information to the carrier prior to pick up. The driver must be HAZMAT trained in order to pick up the shipment. The carrier has to specifically make sure a HAZMAT driver is assigned to the shipment. If the shipment is LTL, it cannot be mixed with certain other classes of HAZMAT or commodities. That’s why it’s important to know the class before pick up.

Temperature requirements are another area of great miscommunication. “heated”, “protect from freeze”, “keep above 10 degrees C” and “must maintain between 10 and 15 degrees C” mean completely different things to a carrier. Different equipment may be used in each case and it also impacts what other LTL can ship with a particular product. Make sure you let your temperature controlled carrier know the exact temperature requirements so they can plan your pick up.

In many cases few shippers even consider shipment value when tendering a shipment to a carrier. However, if your shipment is valued at over $2.00 per pound, a carrier may think twice about wanting to take the shipment. There is great risk for a carrier transporting high value goods. If you have high value freight, this should be communicated in advance to a carrier.

Carriers generally expect to have a dock facility at truck height to load and unload the freight. If your pick up or delivery doesn’t have a dock, the carrier needs to know. Your shipment may have to be re-delivered on a flat-bed, or straight truck with a power tailgate.

If your facility practices live load vs. drop trailers, the carrier needs to know in advance. In many cases it may not be possible to spot an empty trailer on short notice. Loading time is also another key factor that should be communicated to the carrier in advance. A long loading/waiting to be loaded time may eat up the hours a driver has left to drive and result in your freight being delayed by a day while the driver is legally off duty.

Required transit time is an important piece of information for the carrier. It could impact whether they send a driver at the beginning of his shift vs. end of his shift. The carrier may have to dispatch a team of drivers to meet the delivery requirement. In some cases, the required transit time may not even be possible while adhering to the speed limit and hours of service regulations.

Having the customs paperwork filled out correctly, the name of the customs broker, who the clearing customer is for clearance purposes, and the border crossing point is critical to prevent shipment delay for shipments crossing the border.

The carrier may not be aware they need to book an appointment, or have the hours to wait in line to get loaded. Letting the carrier know in advance allows them to plan accordingly.

In a recent study released by The Conference Board of Canada titled, “We Have Been Here Before” it concludes that since deregulation in 1987 as a whole, the transportation industry has absorbed cost increases while passing most of their productivity gains on to shippers.

In a recent study released by The Conference Board of Canada titled, “We Have Been Here Before” it concludes that since deregulation in 1987 as a whole, the transportation industry has absorbed cost increases while passing most of their productivity gains on to shippers.

Some of the key findings of the study are:

From 1986 to 2003, trucking industry total factor productivity (TFP) increased by an average 1.7 per cent per year. Meanwhile, prices increased by just 0.8 per cent per year on average in nominal terms, while prices dropped in real terms. This adjustment occurred despite average increases in input prices (labour, fuel, capital,etc.) of 2.6 per cent per year.

Put another way, 87 per cent of productivity gains have been used to hold down output prices in the face of rising fuel, capital, labour, and other costs, rather than to increase profit.

This study echoes what most people who work in the transportation industry know to be true. That trucking is a highly competitive industry where survival depends on productivity gains and price competitiveness. Generally, any price increases passed along to customers are absolutely necessary and reflective of input cost increases. And, as the study concludes, most of all productivity gains are used to offset input price increases experienced by the carriers in terms of fuel, labour and insurance cost increases.

Many shippers believe that volume buys lower rates. While this is true to some extent, there is a limit to this logic. Think about it. If you drive from point A to point B and add up your time, wear and tear per mile, cost of fuel, etc. Then do it 100 times and see if your costs go down. They don’t. The real challenge to getting costs down is to work with your transportation provider to take cost out of the system. Here are some areas where you can work with your carrier to help reduce transportation costs:

Any time spent by the carrier waiting to get loaded or unloaded, is waste. It’s productive time that is not being used for a productive purpose. Take steps to reduce waiting time at your facility. Get trucks in and out fast. Many shippers have policies of appointment system and/or first come first served systems. While neither are perfect, the focus has to be on getting the average waiting time for carriers down. In the end, any unproductive time for the carrier will find its way into your rates.

Many shippers take the approach of trying to eliminate or reduce assessorial charges to unrealistic levels. Unrealistically low, or non-existent assessorial charges introduce an element of risk for the carrier. A carrier’s margin is slim and an unexpected cost without compensation can make or break their profitability. A carrier will have to charge more in their base rate to compensate for the “uncertainty factor”. Talk with your carriers and negotiate fair and equitable assessorial charges. This will allow the carrier to price their line-haul economically.

The best, most experienced drivers often have first choice on the loads they want to take. These most experienced drivers are the low cost drivers. They know the paperwork, their routes, and how to drive in the most efficient manner. If these drivers enjoy picking up and delivering at your facility, you’ll be come a shipper of choice. These drivers will want to frequent your facility.

Paying on time is critical for a carrier’s cash flow. Trucking is a cash intensive business. Many of the costs like labour and fuel are paid up front while the revenue gets paid to the carrier much later. If you’re using a freight payment company to pay your freight bills, make sure they are paying fairly. Many freight payment company’s make their money on the interest on your money. That means that to make money, they have to pay your carriers slower than you pay them. Many do this through strict payment rules and rejecting invoices that often go back to the shipper and don’t get resolved for months. These costs will eventually end up in your rates if you don’t take action to make the payment process easier.

In conclusion, shippers have a great influence on the cost of transportation. Shipping policies and procedures have a huge influence on the shipping rates you pay. Your carriers operate on thin margins and competitive marketplace ensures they are squeezing out any savings or productivity gains on their end. Work with your carriers to generate ideas and policy changes to help reduce or offset cost increases in transportation.