The demand for truck drivers has never been higher; the industry is growing, adopting new technology and is a key driver of our economy. Ever considered a career in trucking? Maybe you should!

A rewarding career

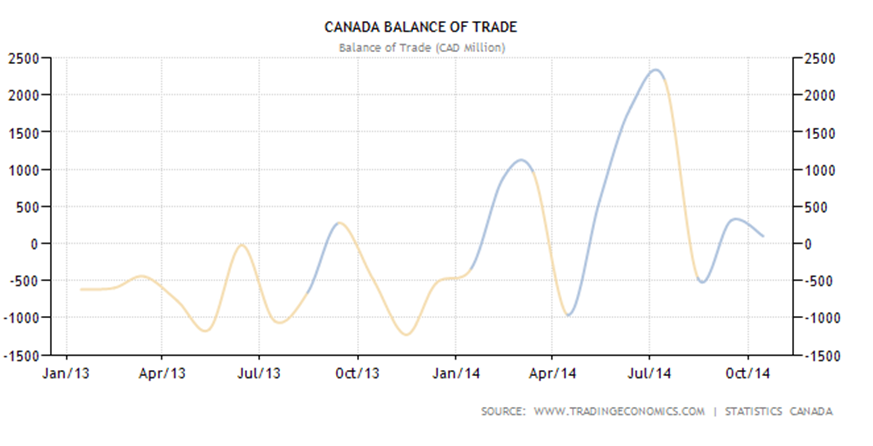

Almost every consumer product and foodstuff arrives by truck to the end consumer. Without truck drivers, our economy wouldn’t be able to function, let alone feed, cloth, and house a nation. The trucking industry is an important part of the Canadian Economy.

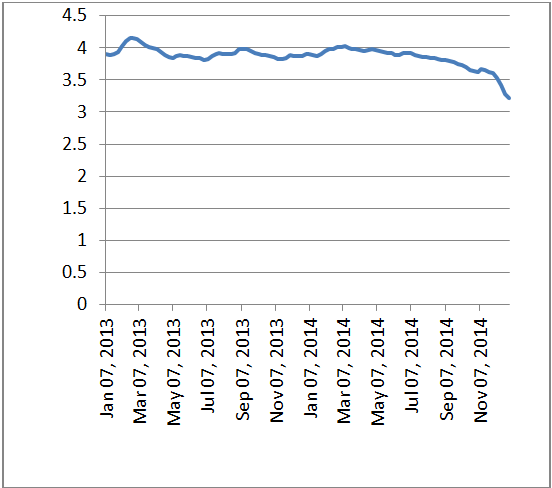

You’ll be in high demand

According to a recent Conference Board of Canada study (2013), it’s predicted that across Canada there will be a shortage of between 16,600 and 33,000 drivers by 2020. This is largely based on industry growth and a high number of retirees in the years to come.

Recession Proof

Because of the general lack of truck drivers, during the last recession, trucking companies were still hiring. This trend is expected to continue as the demand for drivers grows.

Choice and Freedom

Due to the high demand for truck drivers currently and for the foreseeable future, you’ll be able to pick your employer. If one is not a good fit, you’ll be in such high demand that you’ll be able to choose a trucking company that is a better fit for you.

Cutting Edge Technology

The trucking industry is becoming more technologically advanced every year. From onboard GPS vehicle tracking to satellite computer systems and communications technologies, the truck driver of the future will be more ‘wired’ than ever before.

Lots of Training Resources

There are a lot of training resources for truck drivers such as: the Professional Truck Driver Institute, Trucking HR Canada or a provincial authority, such as the Atlantic Provinces Trucking Association.

Opportunities for Advancement

There are career paths beyond truck driver that can lead to Driver Trainers, Driver Supervisors as well as Fleet Management and Operations Management careers.

Choice of Work

Not all truck drivers are on the road for extended periods of time. Of course, many people choose long haul positions because of the freedom and the ability to travel they offer, but there are also many local and short haul positions available in the industry.

An Industry That’s Actively Seeking Women

According to statistics, 97% of drivers are men. This is something the industry wants to change. If you’re a female looking for a challenging and rewarding career, trucking may be for you.

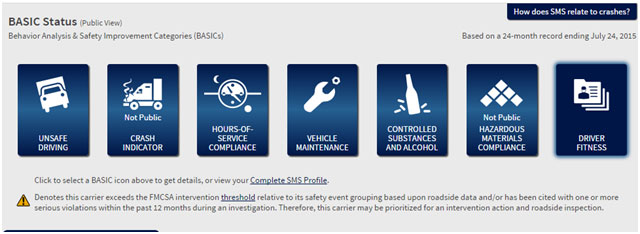

XTL Transport is Hiring

If you’re considering a career in trucking, please contact us, we’d love to talk to you. XTL offers many benefits to new drivers, including training and mentoring programs. You can find more information and contact us on our website here.