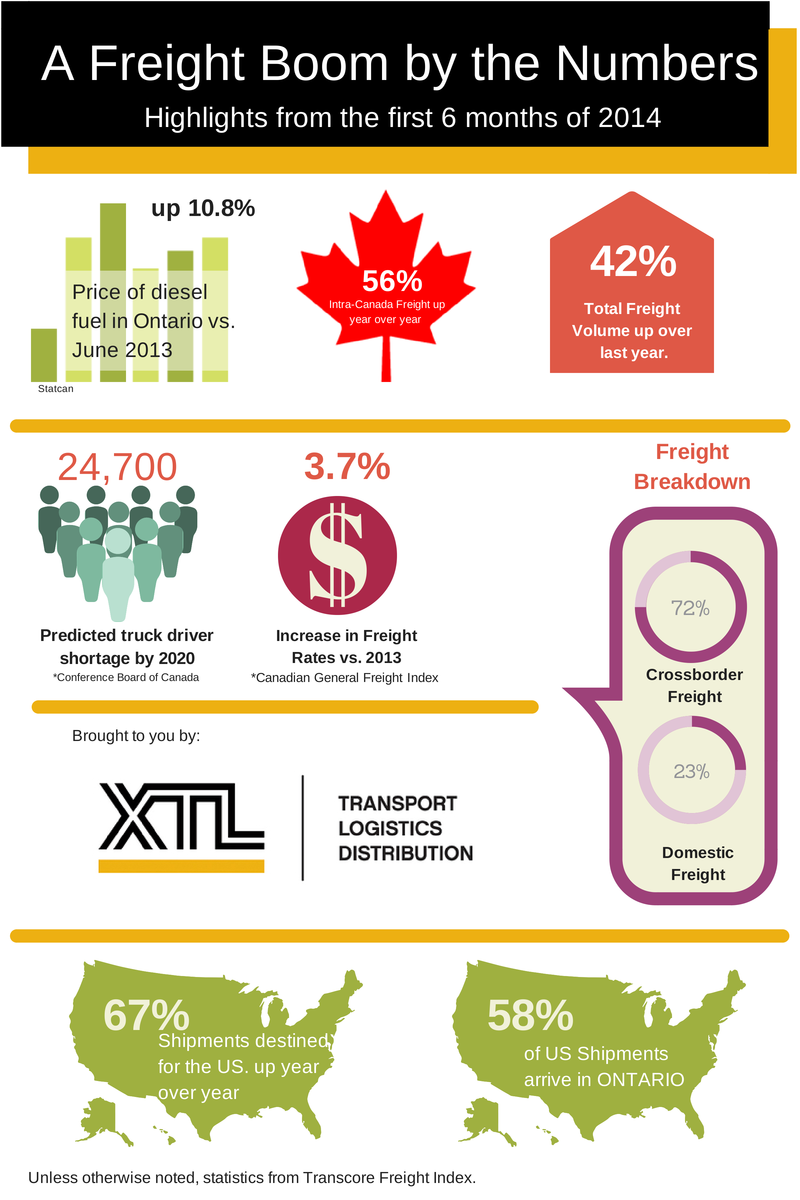

This year; 2015, XTL Transport celebrates 30 years in the trucking industry. Today, XTL is a vibrant national and international asset based transportation Management Company that includes trucking, logistics, warehousing and distribution.

Fast Facts about XTL Transport:

Business Growth

• XTL has grown over 50% since 2007 through expansion into Western Canada.

Terminals and Offices

• Langley, BC

• Airdrie, AB

• Mississauga, ON

• Toronto, ON

• Montreal, QC

• Boucherville, QC

• Quebec City, QC

Equipment:

• Approximately 400 Power Units

• 1200 Trailers including dry, temperature controlled and Refrigerated trailers. These are a combination of tandem, Tridem and quad axle equipment with barn doors and roll up doors.

Warehousing:

• XTL boasts 650,000 square feet of heated warehousing facilities in Toronto and Montreal capable of cross-docking and distribution. Plus, the facilities are fully equipped with rail siding for convenient processing and storage of your rail shipments.

Logistics:

• XTL Logistics provides full 3PL Transportation Management Services including truck brokerage throughout North America. XTL Logistics has the carrier base to get any shipment moving with their strategic partner alliance.

• XTL Logistics has the full backing of XTL’s asset base.

Specialties:

• Since inception, XTL Transport has been an expert in paper transportation. Servicing Northern Quebec, XTL quickly became a premier transporter of paper and newsprint. Plus, XTL’s distribution facilities are specially designed and equipped to handle paper rolls.

• XTL’s TempSolution initiative makes them the unparalleled leader in temperature controlled transport. XTL invests heavily in state of the art insulated trailers with computerized reefer units that maintain and monitor an exact temperature, making these units perfect for pharmaceuticals and other temperature sensitive goods.

• CPG (Consumer Packaged Goods) are a mainstay of XTL’s business today including both the retail, pharmaceutical and medical industries.

Customer Base

• XTL has grown to serve many Fortune 100 and 500 companies in Canada and across North America.

Key Milestones

| 1985 | Opened XTL, and warehousing, plus expanded into the US. Started with 25 trailers, 6 owner-operators and 8 staff members. |

|---|---|

| 1987 | XTL – TIC merge adds 75 owner operators. |

| 1989 | XTL – GTL Truckload & Truckit merge adds 150 owner-operators. |

| 1990 | XTL installs computerized Logistics Systems. |

| 1996 | XTL – TAC merge adds 60 company trucks and agency drivers to the fleet. |

| 1997 | XTL installs mobile satellites in all trucks. |

| 2001 | XTL Logistics is launched. |

| 2004 | XTL opens New Flagship terminal opened in Vaudreuil QC, and a new warehouse in Dorval QC. |

| 2007 | XTL opens office in Langley, BC to expand its dedicated Operations/Services. |

| 2008 | XTL opens office in Airdrie, AB to expand its dedicated Operations/Services. |

| 2012 | Genevieve Gagnon becomes President of XTL and XTL launches new Corporate identity Logo & sub-branding Logo’s. |

| 2014 | Operations for dedicated & local city operations management moves to Boucherville QC. |

| 2015 | Technological advancements continue to be at the forefront |

XTL has managed to grow and prosper in a very difficult and competitive industry over the last 30 years largely thanks to their employees and management, in combination with strong customer relationships built over three decades.

You too, can leverage XTL’s 30 years of transportation experience by contacting the today and book an appointment with one of their logistics experts to review ways in which they can help improve your logistics systems.